Researchers have discovered a rare and useful behaviour in a new class of magnetic materials called altemagnets, specifically in a compound named chromium antimonide (CrSb).

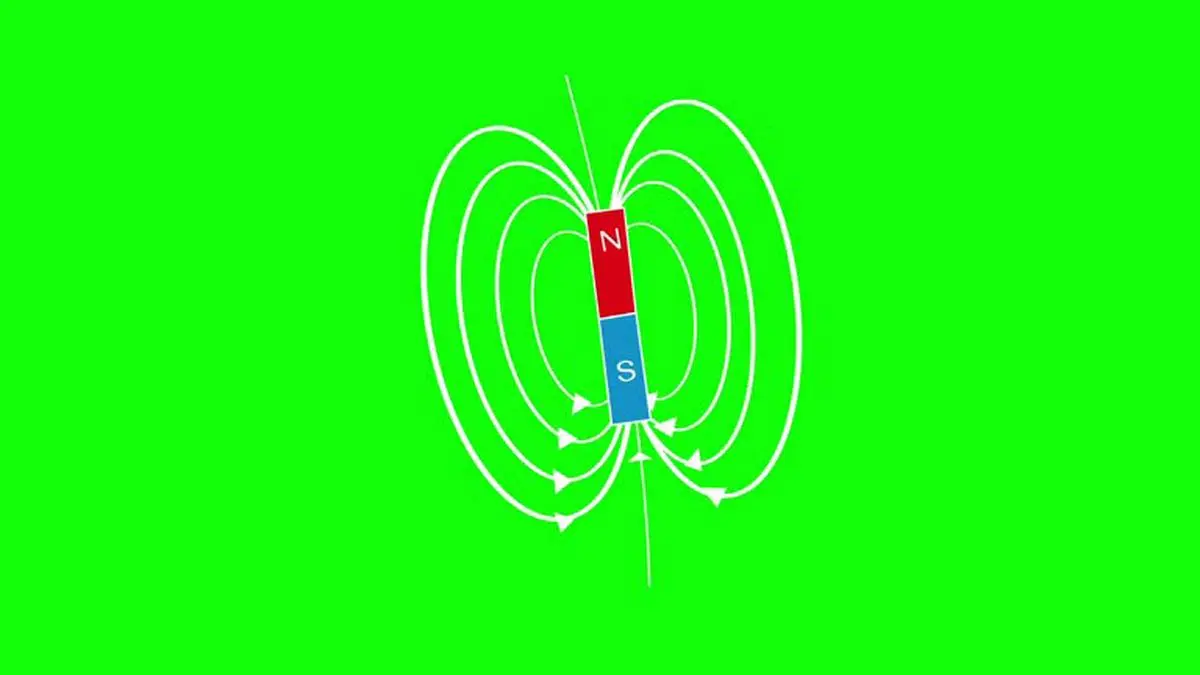

Altermagnets are magnetic materials whose surface (outside) display no magnetic properties — they won’t stick to a fridge. But the ‘insides’ have magnetic properties.

Altermagnets combine the best features of ferromagnets (like fridge magnets) and antiferromagnets (which cancel out their own magnetism). Although they show no external magnetism, their internal electron behaviour can be highly useful for advanced technologies like spintronics, which use electron spin rather than charge.

CrSb stands out for its strong magnetic order, which lasts well above room temperature, and a giant “spin-splitting” effect — over 30 times that of room temperature — making it a top candidate for practical applications.

Now, scientists at the SN Bose National Centre for Basic Sciences (SNBNCBS) have discovered a new property in CrSb called direction-dependent conduction polarity (DDCP). When current flows along the layers of the crystal, electrons carry it (n-type behaviour). But across the layers, the current is carried by holes (p-type behaviour). This switch, depending on direction, is extremely rare and challenges the conventional p-type/n-type classification of materials.

CrSb is the first altermagnet known to show this dual nature. It could allow future devices — like solar cells or thermoelectrics — to function without combining different materials or doping, making them simpler, smaller, and more efficient. Made from abundant, non-toxic elements, CrSb is also environmentally friendly. “It holds great promise for the next generation of electronic and spintronic devices,” says a press release.

Phase-changing emulsion

Researchers at the Fraunhofer Institute, Germany, have developed emulsions made of phase-changing materials (PCMs) and water, or mixtures of water and glycol for applications such as air conditioning inside buildings and cooling industrial machinery.

PCM emulsions are a mix of paraffins and water, or water-glycol, and are used primarily in the mobility sector, where the addition of glycol keeps the mixture from freezing.

The researchers used paraffins, which are dispersed or emulsified in water, or the water-glycol mixtures. Surfactants stabilise the ultrafine paraffin droplets distributed throughout the water, which lends the mixture thermal and mechanical stability.

The emulsions use the high energy density of paraffins during the phase transition from solid to liquid. Because the paraffins are emulsified in water, they can remain liquid regardless of their phase state in the emulsion that is created and can be used as heat transfer liquids in heating and cooling networks — meaning that the mixtures can be pumped through pipes. During the phase change, the PCMs absorb or release large amounts of heat even as their temperature remains constant. This allows for achieving twice the storage density of water — which is currently used as a heat carrier in conventional heating and cooling supply networks — in the PCM melting range while keeping the volume the same.

In addition to their high storage density, PCM emulsions also have a number of other advantages. Owing to the high heat storage capability of PCMs, systems that use them can be designed to take up less space.

More Like This

Published on July 14, 2025