With the rising use of electric vehicles (EVs), the paucity of fast-charging options is a major challenge — high-speed chargers need over 1 megawatt of power, enough to run 1,000 homes. Existing charging stations use line-frequency transformers made of copper and iron, making them bulky, costly and inefficient due to multiple power conversion stages.

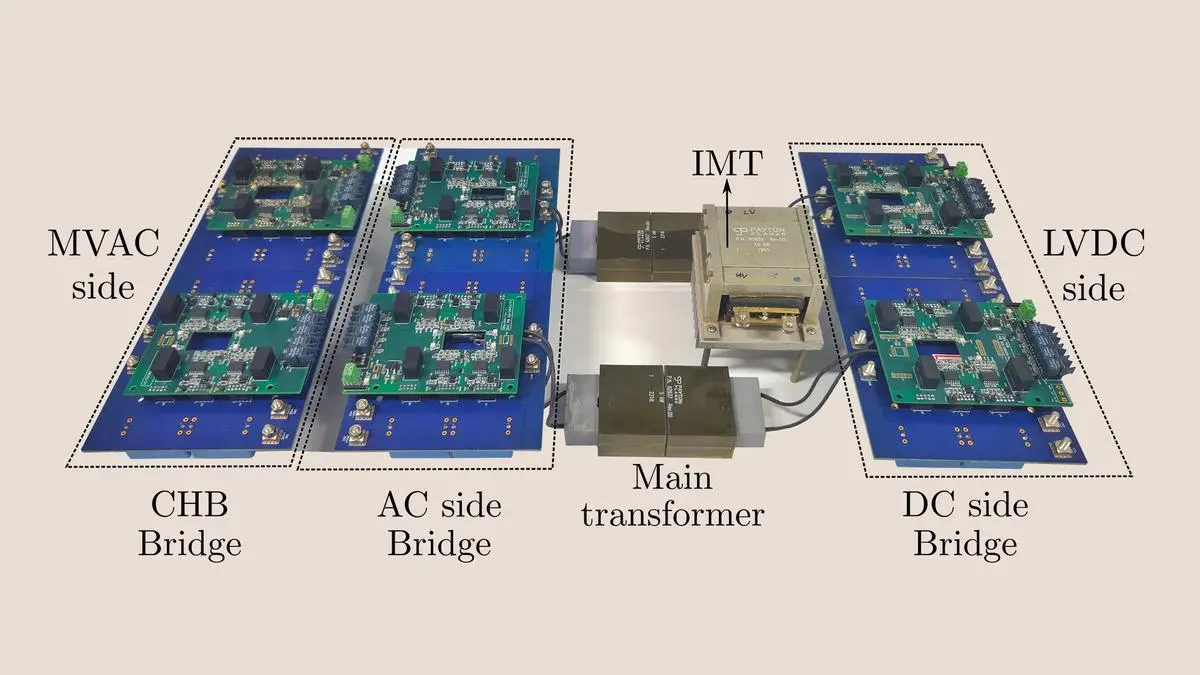

To overcome this hurdle, researchers at the Department of Electrical Engineering, Indian Institute of Science, in collaboration with Delta Electronics India, have developed a cascaded H-bridge (CHB) multi-port DC converter that connects directly to the medium-voltage AC grid. This eliminates the need for large transformers, cutting cost, size and material use.

The converter can simplify EV charging infrastructure and boost efficiency by 3–5 per cent, a major gain at megawatt scale.

“Our invention streamlines the process between the grid, storage and vehicle battery, offering significant energy savings and a smaller environmental footprint,” says Kaushik Basu, Associate Professor at IISc, in a write-up in in-house publication Kernel.

The bidirectional converter can power multiple vehicles, store energy locally in batteries and even feed power to the grid during outages. This ensures reliable supply, especially for critical facilities like hospitals.

A 1.2 kW lab prototype achieved over 95 per cent efficiency, and the team is scaling it up further.

The technology also has potential use in data centres, wind farms and rail systems, enabling high-efficiency conversion at medium voltages.

IISc and Delta are setting up a 2,500 sq ft lab to demonstrate a megawatt-scale converter capable of charging a 200 kW bus and a 50 kW car directly from an 11 kV grid.

Light, flexible solar cell

Researchers from Aalto University and University of Cambridge have discovered that carbon-based organic radicals — molecules with an unpaired electron — can act as efficient semiconductors, paving the way for a new class of lightweight, flexible solar cells.

Unlike conventional organic solar cells, which need two carefully matched materials to generate and move charges, these radicals can function as single-material semiconductors. Their lone electron makes them excellent charge carriers. When exposed to light, a thin film of these radicals can generate and separate electrical charges with 100 per cent efficiency, converting all absorbed light into usable energy, says a press release from the university.

Traditional silicon solar panels are heavy, rigid and opaque, limiting their use in devices such as smart windows or wearables. In contrast, radical-based solar films could be thin, flexible, coloured and lightweight — just a few hundred grams for an entire panel. They can be bent or shaped easily, and their manufacturing process is simple and scalable.

“Our work shows that radical-based semiconductors can generate electricity without energy losses,” says Petri Murto, Academy Research Fellow at Aalto University. The discovery builds on earlier research, where radicals developed for LED materials showed unexpected charge transfer behaviour — electrons could move freely between molecules instead of staying bound.

More Like This

Published on October 20, 2025