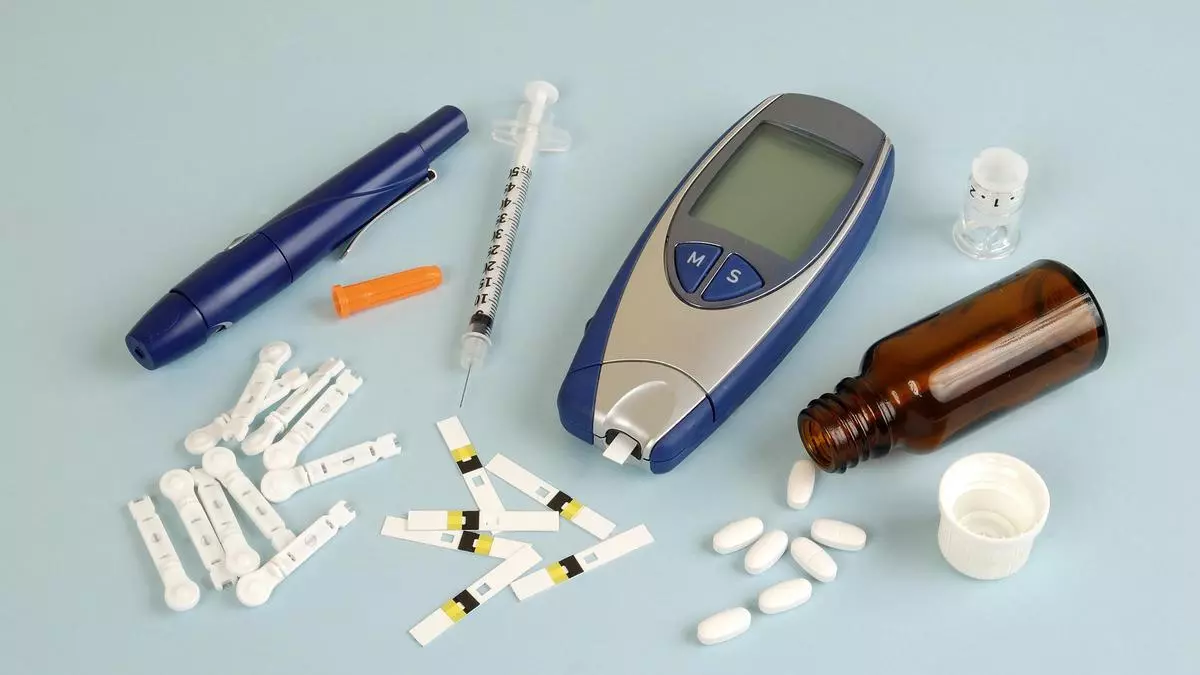

In 2021, approximately 537 million people had diabetes; this number is set to rise to 643 million by 2030 and 783 million by 2045, data from the International Diabetes Federation (IDF) shows.

Diabetes can lead to multiple health issues and is a leading cause of mortality globally, along with cardiovascular disease (CVD), respiratory disease, and cancer.

Insulin, a hormone that regulates blood sugar levels, is injected to help manage diabetes. The insulin — in the form of a liquid solution or a suspension — is injected subcutaneously (under the skin). Depending on prescription, it may be taken several times a day. However, the discomfort of needle use and the cost of injectable insulin could impede patient compliance. Research is on to find alternative delivery of insulin through inhalation, or rectal, buccal or oral routes.

Of these, oral insulin delivery is the most convenient. However, since insulin is a peptide (short chain of amino acids) it is acted upon by the enzymes in the body that break down macromolecules in food into smaller molecules fit for metabolism. When insulin is broken down by enzymes its ‘bioavailability’ — the time it remains available for use by the body — is reduced.

“The human physiological system acts as a formidable barrier to insulin, limiting its bioavailability,” says a scientific paper titled ‘An overview of oral insulin delivery strategies’, by scientists from Institute of Chemical Technology (ICT), Mumbai.

The paper, a review of literature, focuses on oral insulin delivery strategies (OIDS) for increasing the bioavailability of oral insulin, including nanoparticles, microparticles, nano-in-microparticles, hydrogels, tablets, capsules, intestinal patches, and ionic liquids.

A viable option

Oral insulin can enhance patient compliance and drive down prices significantly, but its development has been a challenge for the scientific community.

“Oral insulin is one of the most researched subjects… Unfortunately, none of the products have reached commercial stage or success yet,” says Ratnesh Jain, Associate Professor at ICT. However, “such an option can be viable in the future,” he told Quantum.

Since insulin is sensitive to the acids and enzymes in our digestive system, which break it down, the challenge is in ensuring the drug makes its way unaffected to the intestinal lining.

The strategy is to temporarily block the enzyme action through alternative chemical agents.

“Sufficient bioavailability is needed for drugs to function. We are trying to suppress acid/enzyme mixture and, at the same time, create temporary pores for the peptides to pass through in the stomach or intestinal barriers, so bioavailability can increase,” he said.

The intestinal lining also contains various pores for water, vitamins and nutrients to enter the blood stream. However, these pores are too small for drugs like insulin. Permeation agents (chemical agents) are used to increase the pore size.

These pores, together with the reduced activity of enzyme, allow faster transfer of drugs from intestine to blood. This is known as the ‘trojan horse’ approach.

“Oral peptide delivery is a major research topic in our lab,” Jain said.

Advancing technology

At ICT, researchers have successfully used nanomaterials, chemicals and excipients to increase the bioavailability of insulin.

“Formulation components are key to control this challenge,” Jain says. Formulation components like sugars, fatty acids, and polymers interact with acids and enzymes differently and they inhibit the enzymes and create temporary small pores in the barriers. “A large number of components need to be screened for this activity and, sometimes, a right ‘recipe’ needs to be created which can work for oral delivery of peptides. We are still screening various recipes that can work for insulin,” he said.

There has been limited success so far. “One of the most successful strategies is the oral delivery of semaglutide, where the patent technology of formulation components has allowed higher bioavailability.” He added that there are drugs in various clinical stages of development.

An added challenge he points out is that early development is expensive and the Indian pharma industry can only fund late-stage developments. “Early-stage development requires government support,” Jain says. Another major issue is the need for a regulatory path for the researchers.

“In our lab, we have established an industry-acceptable regulatory path and this is one of the major reasons why industry has come forward to collaborate with us,” he said.

This collaboration will, hopefully, soon enable thousands of diabetics to put down their insulin syringes and pop a tablet instead.

SHARE

- Copy link

- Email

- Facebook

- Telegram

- LinkedIn

- WhatsApp

- Reddit

Published on November 27, 2022